Water Storage Tanks Plastic: A Complete Guide

When you need a reliable water supply, plastic water storage tanks are the modern standard. They offer a durable, rust-proof, and cost-effective way to keep water on hand, acting as your own personal reservoir for a home, farm, or business. These tanks are specifically engineered to keep your water safe from contamination and the elements.

Why Choose a Plastic Water Storage Tank

Having a consistent water supply is non-negotiable, whether you’re running a household, an agricultural operation, or an industrial site. In an age of unpredictable weather and aging infrastructure, putting all your trust in the municipal grid can be a risky move. This is exactly where a plastic water storage tank offers some much-needed peace of mind.

Imagine having a dedicated reserve, ready for drinking, irrigation, or emergencies. This isn’t just about storing water; it’s an investment in your own self-sufficiency. Modern polyethylene tanks have become the top choice for a reason—they simply outperform traditional materials like steel or concrete in almost every way that matters.

The Clear Advantages of Polyethylene

One of the biggest wins for plastic is its complete immunity to rust and corrosion. Metal tanks will inevitably break down over time, potentially leaching contaminants into your water. High-quality polyethylene, on the other hand, holds its ground, keeping both its structure and your water pure for years. This natural resistance means you don’t have to worry about expensive liners or the constant maintenance that comes with rust prevention.

On top of that, plastic tanks are surprisingly lightweight. This makes a world of difference when it comes to transportation and installation. You can often get a plastic tank into position with just a few people, no heavy machinery required. That makes it a practical solution for remote properties or sites with tricky access, saving you money and a lot of headaches on installation day.

A plastic water storage tank gives you a buffer against supply interruptions. It empowers you to manage your most critical resource on your own terms, making sure you have water exactly when you need it.

A Proven Solution for Modern Challenges

The value of these tanks really shines in areas facing water uncertainty. In places like California, plastic water storage tanks are a critical tool for navigating the state’s wildly unpredictable water supply, which swings between severe droughts and major floods. These tanks provide essential storage for all kinds of needs where municipal supplies might fall short. It’s a clear example of how vital these solutions have become.

Ultimately, the combination of durability, low maintenance, and affordability makes plastic the smart choice for modern water storage. If you’re looking to secure a clean source of water, you can find a wide variety of potable water storage tanks designed to meet strict safety standards.

Finding the Right Type of Plastic Water Tank

Choosing the right shape and style for your water storage tanks plastic isn’t just about what looks best—it’s about performance, stability, and practicality. You wouldn’t use a sports car to haul lumber, and you wouldn’t use a transport tank for stationary home storage. Getting this part right from the start ensures your setup is efficient, safe, and built to last.

Every tank design is engineered for a specific job. Some are made to be space-savers on a tight property, while others are built tough to handle the bumps and rattles of transport. Let’s break down the main types to see which one fits your needs.

As you can see, if you’re looking for a water storage solution that won’t rust, is easy to move, and doesn’t break the bank, plastic is almost always the best place to start.

The table below gives you a quick overview of the most common tank types, helping you match your project to the right container.

Comparing Plastic Water Tank Types

| Tank Type | Primary Use Case | Key Advantage | Common Capacities |

|---|---|---|---|

| Vertical Tank | Stationary storage (residential, farm) | Maximum volume on a small footprint | 200 – 10,000 Gallons |

| Horizontal Tank | Mobile transport (trucks, trailers) | Low centre of gravity for stability | 50 – 2,500 Gallons |

| IBC Tote | Industrial & commercial logistics | Stackable, easy to move with a forklift | 275 – 330 Gallons |

Ultimately, the best choice comes down to one simple question: will your tank be staying put, or will it be on the move?

Vertical Tanks For Stationary Storage

When you picture a classic water tank, you’re probably thinking of a vertical one. These are the workhorses of residential, agricultural, and commercial storage for a good reason. Their tall, round design is incredibly smart, offering maximum storage capacity with a minimal ground footprint.

This design makes them perfect for spots where space is tight. You can tuck a slimline vertical tank right next to a house to collect rainwater or set up a larger one behind a barn without chewing up valuable land. Since they’re designed to stay in one place, they are built for stability and long-term durability against the elements.

Horizontal and Transport Tanks For Mobile Needs

Horizontal tanks, on the other hand, are built low and wide for one main reason: stability. With their low centre of gravity, they are the undisputed choice for transporting liquids. You’ll see these tanks—often called leg tanks or pickup tanks—strapped onto trailers or sitting in the beds of trucks in farming, construction, and landscaping operations.

Their rugged build is designed to prevent sloshing and tipping when moving across uneven ground, a critical safety feature when you’re hauling water, fertilizer, or other chemicals. They are engineered specifically for the stresses of movement.

Choosing the right tank shape is the first step in building a reliable system. A vertical tank provides efficient, stationary storage, while a horizontal tank delivers the stability required for safe transport.

Intermediate Bulk Containers (IBCs) For Industrial Use

For industrial, commercial, or shipping applications, the Intermediate Bulk Container—or IBC—is king. These units are a brilliant all-in-one solution: a tough plastic bottle protected by a galvanized steel cage, all mounted on a pallet for easy handling with a forklift or pallet jack.

IBCs are prized for their standardized footprint, which makes logistics a breeze and maximizes warehouse space. Their modular nature means they can be moved, stacked, and plugged into different systems with ease. If you’re working in an industrial setting, knowing the exact dimensions is crucial; you can find a complete guide on IBC tote measurements to make sure they fit your workflow.

The cage doesn’t just protect the inner container; it allows for secure stacking, which is essential when you need to use every inch of vertical space. With built-in valves and large top openings, filling and dispensing are simple, streamlining processes in everything from food production to chemical manufacturing. This mix of durability, portability, and efficiency is why IBCs are a cornerstone of modern bulk liquid handling.

How Your Plastic Tank Is Made to Last

Ever looked at a massive plastic water tank and wondered how it can stand up to decades of sun, rain, and pressure without failing? It’s not just a big plastic bucket. It’s a seriously engineered piece of equipment, and its incredible strength comes down to the clever science behind the materials and the manufacturing process.

The secret to its longevity really starts at the molecular level with the type of plastic used. Most tanks aren’t just one kind of plastic, but a specific blend designed for the job. Getting this right is the first step in creating a container that you can rely on for years to come.

This careful selection of materials is what separates a high-quality tank from one that will crack and fail prematurely.

Choosing the Right Polyethylene Material

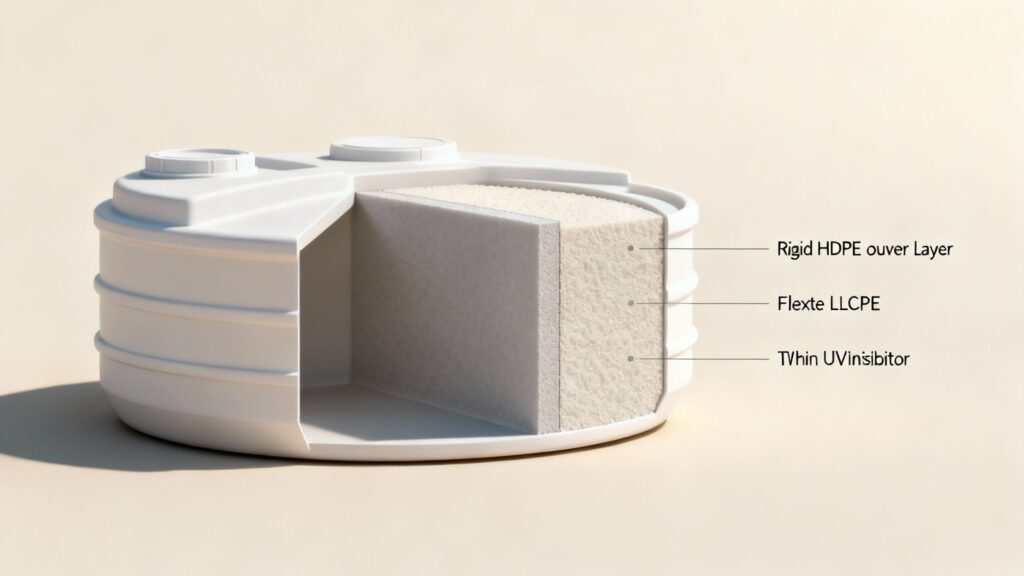

The two heavyweights in the world of plastic tanks are High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE). They might sound almost the same, but they bring very different qualities to the table.

Think of HDPE as the tank’s skeleton. Its molecules are packed tightly together, giving it incredible stiffness and structural integrity. This is what allows the tank to hold its shape under the immense weight of the water inside.

LLDPE, on the other hand, is the flexible muscle. Its molecular chains are more loosely arranged, which makes it much more forgiving. It can handle impacts, ground movement, and temperature swings without cracking under pressure.

Most top-tier tanks are actually made from a strategic blend of both. You get the rigid strength of HDPE combined with the tough, impact-resistant nature of LLDPE, resulting in a tank that’s the best of both worlds.

The Rotational Moulding Process

So, how do you turn plastic powder into a massive, seamless tank? The magic happens with a process called rotational moulding, or “rotomoulding” for short. This is what gives modern tanks their superior strength.

Here’s a quick look at how it works:

- Step 1: Loading. A carefully measured amount of polyethylene powder gets poured into a huge, hollow mould shaped exactly like the finished tank.

- Step 2: Heating and Rotating. The mould is sealed and then moved into a massive oven. While it heats up, it rotates on two different axes at once—picture a spinning, tumbling cube. This motion ensures the melting plastic evenly coats every single inch of the mould’s interior.

- Step 3: Cooling. Still spinning, the mould is moved out of the oven and into a cooling station. This slow, controlled cooling process is crucial; it lets the plastic harden into a solid, uniform layer without creating weak spots.

- Step 4: Demoulding. Once it’s cool, the mould is opened, and out comes a perfect, single-piece tank.

The most important takeaway here is that rotomoulding creates a tank with no seams. Seams and welds are almost always the first place a container will fail. By eliminating them entirely, you get a tank that is naturally stronger and virtually leak-proof.

Built-In Sunscreen: UV Inhibitors

Any plastic left outdoors has one major enemy: the sun. Over time, ultraviolet (UV) rays break down plastic, making it brittle and weak. That’s where UV inhibitors come in.

These additives are mixed right into the plastic resin before the tank is even made. Think of it as a powerful sunscreen that’s built directly into the tank’s material, protecting it from the inside out. This protection is non-negotiable for a tank expected to last, often for more than 20 years.

But that’s not all. A quality tank doesn’t just protect itself—it protects the water inside. The opaque material is specifically designed to block all sunlight from getting through. Without light, algae can’t grow. This simple feature keeps your water clean and pure without you having to constantly add chemicals, ensuring the tank and its contents stay in top condition.

Making Sense of Safety Certifications

When you’re looking at different plastic water storage tanks, the labels can look like an alphabet soup of codes and acronyms. It’s easy to get lost, but those certifications are your single most important guarantee of quality and safety. They aren’t just suggestions; they prove the tank has been put through its paces to meet strict standards for a specific job.

Figuring out what these labels mean is the key to making sure your stored liquid is safe, whether it’s for drinking, farming, or industrial use. A tank without the right certification is a gamble, one that could put safety and your compliance with regulations at risk.

The Gold Standard for Drinking Water: NSF and ANSI 61

If you need a tank for potable (drinkable) water, there’s one certification you absolutely must look for: NSF/ANSI 61. Think of it as the ultimate seal of approval for water purity. It guarantees the tank’s material is safe for contact with drinking water and won’t leach any nasty chemicals into your supply.

A tank carrying this certification has gone through rigorous third-party testing to meet public health standards. For any application where people or animals will be drinking the water, this is completely non-negotiable.

Here’s what it guarantees:

- No Harmful Leaching: The plastic won’t release things like volatile organic compounds (VOCs), heavy metals, or other contaminants into the water over time.

- Material Safety: The raw materials used to make the tank are confirmed to be non-toxic and built for long-term water contact.

- Taste and Odour Neutrality: The tank won’t give the water any weird tastes or smells, keeping it fresh and clean.

Without this certification, you have no real way of knowing if the plastic is truly safe for drinking water. It’s a critical detail to check before you buy.

UN and DOT Ratings for Secure Transport

When you’re moving a tank full of liquid—especially anything potentially hazardous—you need to know it can handle the journey. That’s where UN/DOT ratings come in. These codes, issued by the United Nations (UN) and the Department of Transportation (DOT), certify that a container has passed a series of tough performance tests.

Think of a UN/DOT rating like a crash-test certification for a tank. It proves the container can handle drops, vibrations, stacking, and internal pressure without breaking or leaking. It’s all about ensuring the contents stay safely inside during transport.

These ratings are vital for any business in logistics, agriculture, or the chemical industry. Using a non-rated tank for transport isn’t just a bad idea; it can lead to serious legal trouble and fines for being non-compliant.

Food-Grade vs. Non-Food-Grade Plastic

Finally, it’s important to know the difference between “food-grade” and “non-food-grade” plastic. A tank can be made from food-grade material, but that doesn’t automatically mean it’s certified for drinking water—for that, you still need the NSF/ANSI 61 rating.

- Food-Grade Plastic: This simply means the material itself is safe to come into contact with food. It’s a solid choice for storing things like syrups, oils, or bulk ingredients in the food and beverage industry.

- Non-Food-Grade Plastic: This material is made for utility purposes where absolute purity isn’t the main concern. It’s perfect for things like irrigation water, rainwater collection for your garden, or storing various industrial fluids.

Managing water quality is a major public health focus in Canada. Reports from the National Collaborating Centre for Environmental Health show that while older concrete or steel tanks often had issues with seepage and contamination, modern plastic tanks significantly reduce these risks. Choosing a tank with the correct certifications is your first and best line of defence in keeping your water safe and clean.

When you start shopping for an Intermediate Bulk Container (IBC), you’ll run into three main options: new, rebottled, and reconditioned. Each one strikes a different balance between cost, cleanliness, and overall condition. Figuring out these differences is the key to picking the right IBC for your job without overspending or cutting corners on safety.

This isn’t just about finding the cheapest option. It’s about matching the tank’s history with its future use. For the highest purity standards, nothing beats a brand-new tank. But for many other jobs, a professionally cleaned and inspected unit is a perfectly smart and economical choice.

Let’s break down what each of these conditions really means.

New IBC Totes: The Pristine Choice

A new IBC tote is exactly what it sounds like—it’s factory-fresh from top to bottom. The inner plastic bottle and the outer steel cage have never been used. They haven’t held a single drop of anything, which guarantees you’re getting a completely sterile container with perfect structural integrity.

This makes new water storage tanks plastic the only real option for applications where hygiene is non-negotiable.

- Drinking Water: If you’re storing potable water, you absolutely need a new, NSF-certified tank. No exceptions.

- Pharmaceuticals: When product purity is critical, you can’t afford even the slightest chance of contamination.

- Food and Beverage: Any ingredients meant for human consumption must be stored in new, food-grade totes.

Bottom line: if you need 100% certainty that your product remains pure, a new IBC is the industry standard. It gives you complete peace of mind, knowing it has a clean history and fresh certifications.

Rebottled IBC Totes: The Smart Hybrid

A rebottled IBC is a clever compromise that gives you the best of both worlds. It pairs a brand-new, sterile inner plastic bottle with a used, professionally inspected, and refurbished steel cage. You get the full benefit of a completely untouched container for your liquids but at a lower cost than a totally new unit.

Think of it like buying a certified pre-owned car that has a brand-new engine. The part doing all the important work is fresh from the factory, while the sturdy frame has already proven itself. This makes rebottled totes an excellent choice when you need sterility but want to be smart with your budget.

A rebottled IBC tote combines a pristine, food-grade plastic bottle for product safety with a refurbished cage for cost savings. It’s the go-to option when hygiene is critical but a fully new unit isn’t absolutely necessary.

Reconditioned IBC Totes: The Economical Workhorse

A reconditioned IBC is a used tank that has been put through a rigorous professional cleaning and restoration process. This involves high-pressure washing, steam cleaning, leak testing, and replacing parts like valves and gaskets to ensure the tote is safe and ready for its next job. These units offer major cost savings and are a great environmentally friendly option.

Because they’ve held other materials before, reconditioned totes are strictly for non-potable and non-consumable products. They are the workhorses for countless industrial, agricultural, and general-purpose jobs.

- Irrigation water for farms and landscaping

- Rainwater collection for gardens or washing equipment

- Industrial chemicals or waste fluids

- De-icing agents or construction site materials

These tanks deliver fantastic value for utility storage. If you’re looking for sustainable options, professional IBC reconditioning services give these durable containers a second life, which is a smart way to get a reliable tank while reducing waste.

New vs. Rebottled vs. Reconditioned IBC Tanks

Feeling a bit stuck? This table breaks down the key differences to help you decide which IBC tank condition is the right fit for your needs and budget.

| Attribute | New IBC Tank | Rebottled IBC Tank | Reconditioned IBC Tank |

|---|---|---|---|

| Inner Bottle | Brand new, never used | Brand new, never used | Professionally cleaned, used |

| Outer Cage | Brand new, never used | Inspected and refurbished, used | Inspected and refurbished, used |

| Best For | Drinking water, food, pharmaceuticals | Food-grade materials, sensitive chemicals | Non-potable water, industrial chemicals, waste |

| Cost | Highest | Moderate | Lowest |

| Food-Grade | Yes, certified | Yes, certified | No |

| UN/DOT Rating | Yes, new certification | Yes, new certification | Yes, recertified |

Ultimately, the best tank for you depends entirely on what you plan to put inside it. For anything you or others will consume, stick with new or rebottled. For everything else, a reconditioned tank is often the most practical and cost-effective solution.

Proper Installation And Maintenance Practices

Getting your plastic water tank set up on a firm, level base is like laying the foundation for a building—it determines everything that follows. When you nail the installation, you’ll avoid leaks, cracks and headaches down the road.

A carefully planned approach also means fewer surprises. Follow the steps below to get it right the first time.

Installation Checklist

- Prepare a firm, well-compacted base such as gravel or concrete.

- Position the tank on a flat surface clear of stones or debris.

- Fit quality ball valves for flow control and threaded adapters to match your piping.

- Install vents or pressure-relief valves to prevent vacuum collapse.

- Perform an initial leak test by filling the tank partway and scanning all fittings.

A rock-solid foundation and attention to detail at this stage set the stage for years of trouble-free service.

Level Base Requirements

Even a slight tilt can create stress points in the tank wall. The base should be level within 5 mm across the entire footprint. For permanent installs, a concrete pad is hard to beat, but a well-compacted gravel bed can work just as well on lighter systems.

Essential Fitting Selection

Choosing the right fittings makes all the difference to performance and safety:

- Ball valves to manage flow without drips

- Pressure-relief vents to protect against implosion

- Flanged vent caps with insect screens to maintain water quality

“The integrity of fittings determines the overall reliability of the tank system.” – Industry Expert

A solid fitting setup cuts the risk of leaks and contamination.

Once your fittings are in place, the next priority is anchoring the tank against wind or seismic activity.

Numbered Installation Steps

- Position the tank and check level with a spirit level.

- Connect inlet and outlet fittings, using sealant tape on every threaded joint.

- Fit vent and overflow pipes to channel excess water safely away.

- Attach mounting straps or anchors if required by local codes.

- Fill the tank slowly, watching each interface for any sign of a leak.

After that, switch your focus to routine checks and upkeep.

Routine Inspection Guidelines

Carry out a quick visual sweep at least twice a year. Look for:

| Task | Frequency | Key Focus |

|---|---|---|

| Visual tank check | Biannual | Cracks, UV spotting |

| Fitting leak test | Quarterly | Valve and seal tightness |

| Cleaning inside walls | Annual | Sediment and biofilm |

| Vent and filter service | Annual | Clear blockages |

Cleaning Inside Walls

- Drain the tank fully and rinse with fresh water to dislodge loose debris.

- Use a non-toxic cleaner and a soft brush to scrub interior walls.

- Rinse well and let the tank air-dry before refilling.

- Inspect vent screens and filters, swapping them out if they’re clogged or worn.

Sticking to this routine stops buildup, reduces contamination and extends your tank’s life. Always refer to the manufacturer’s guidelines for safe cleaning agents.

Seasonal Maintenance Tips

Adjust your checks as the seasons change. In winter, a tank heater can prevent freezing:

- Winterise vents and pipework to dodge ice blockages

- Wrap or insulate the tank when temperatures drop below zero

In summer, keep an eye on algae:

- Provide shade or use natural algaecides

- Flush and top up more frequently during heatwaves

With these simple tweaks for every season, your plastic water tank will deliver reliable service for years to come.

Your Top Questions About Plastic Water Tanks, Answered

Alright, so you’ve got a handle on the different types of tanks, the materials they’re made from, and what it takes to get one set up. But chances are, you still have some practical, day-to-day questions. That’s perfectly normal.

Getting clear answers to these common queries is what turns a good purchase into a great long-term investment. Let’s tackle some of the most frequent questions we hear from people just like you.

How Long Will a Plastic Water Tank Actually Last?

When you buy a high-quality polyethylene tank, you’re not just buying a container; you’re buying peace of mind for decades. If it’s installed correctly on a solid, level base and you give it a bit of basic care, you can easily expect it to last 20 years or more. The real secret is the UV-stabilized resin used in top-tier tanks, which protects the plastic from breaking down under the sun.

Think about the alternatives. Steel tanks eventually rust, and concrete can crack as the ground shifts. A well-made plastic tank, on the other hand, is built in one seamless piece. This rotomoulding process gets rid of the weak spots like seams and joints that cause other materials to fail over time. It’s built tough, for the long haul.

How Do I Stop Algae from Growing in My Tank?

This one is surprisingly simple: algae needs sunlight to live. No light, no algae. The best manufacturers know this, which is why they use opaque, coloured plastic that stops sunlight from getting through to the water. For the ultimate defence, choose a dark colour like black or dark green.

What if you have a lighter-coloured tank? No problem, you just need to be a bit more strategic:

- Location, location, location. Try to place it in a shaded spot or even build a simple enclosure to keep the sun off.

- Seal it up tight. Make sure every lid, cap, and access point is sealed properly. Even small slivers of light can be enough for algae to get a foothold.

- Keep it clean. A quick rinse-out now and then will remove any sediment where algae spores might try to settle.

At the end of the day, preventing algae is all about light control. A dark, opaque tank is your best friend here. It creates an environment where algae simply can’t survive, keeping your water fresh and clean without needing any chemicals.

Can I Use a Plastic Water Tank in a Cold Climate?

Absolutely, but you have to respect the power of ice. When water freezes, it expands by about 9%, and that expansion creates a massive amount of force—enough to crack even the toughest tank. While polyethylene has a bit of flex, it’s no match for a solid block of ice pushing outwards.

Here’s how to protect your tank when the temperature plummets:

- Wrap it up. Insulating the tank with a special thermal blanket or building a small, insulated shed around it works wonders.

- Go underground. Bury your pipes below the frost line. The pipes are often the most vulnerable part of the system, so protecting them is key.

- Add some heat. In regions with seriously cold winters, a tank heater or a simple de-icer is a reliable, set-it-and-forget-it solution.

It’s no surprise that more people are turning to these kinds of reliable water storage solutions. The numbers back it up: the global storage tank market, which includes these plastic models, was valued at around USD 24.49 billion in 2023. North America is leading the charge as homeowners and industries replace older, less reliable materials with modern, safer alternatives. You can dig deeper into these market trends in the full industry report on GrandViewResearch.com.

At IBC Tanks Canada, we stock a huge range of new, rebottled, and reconditioned plastic water storage tanks, plus all the fittings you’ll need to get your system up and running. Find the perfect solution for your project at https://ibctanks.ca.

Article created using Outrank