Your cart is currently empty!

Tag: TDG compliance

-

Your Guide to the Flammable Liquids Placard

A flammable liquids placard is a very specific type of warning sign you’ll see on trucks and large containers. It’s a diamond-shaped, red sign that signals the presence of flammable liquids in certain quantities.

At its core, its job is to instantly communicate a serious fire risk to anyone who comes near it—first responders, transport workers, and the public. This ensures everyone knows to handle the situation with the right safety precautions, whether during routine transport or in an emergency.

Decoding the Flammable Liquids Placard

Think of this placard as a universal, life-saving language understood by emergency crews all across North America. When a firefighter pulls up to an accident, they don’t have time to sift through shipping papers. They need to size up the danger in seconds. This bright red diamond gives them that critical, split-second insight.

It’s easy to see placarding as just another regulatory hoop to jump through, but it’s a vital piece of the hazardous materials communication system. Both Transport Canada’s Transportation of Dangerous Goods (TDG) Regulations and the U.S. Department of Transportation’s (DOT) 49 CFR mandate these signs. This ensures that the same placard means the exact same thing, whether a truck is rolling through Vancouver or crossing the border into New York.

The Anatomy of the Placard

Every single element on a flammable liquids placard is there for a reason. The design is all about maximum visibility and clarity, leaving no room for guesswork. Even from a distance or in bad weather, the message has to be clear.

Let’s break down the core components and what they mean:

- The Colour: The bright red background is no accident. It’s universally associated with fire and danger, grabbing your attention immediately.

- The Symbol: A simple but effective flame icon sits in the top corner, visually screaming “this can catch fire.”

- The Number: The number ‘3’ at the bottom identifies the contents as a “Class 3 Flammable Liquid.” This is a specific hazard class within the larger dangerous goods framework, telling responders exactly what category of risk they’re dealing with.

This powerful trio of colour, symbol, and number creates an unmistakable warning. It tells first responders what they need to know at a glance: the material can easily ignite, and they need to approach with extreme caution using the right fire-suppression gear and tactics. Getting the placarding right is a fundamental act of safety that can stop a minor incident from turning into a catastrophe.

A flammable liquids placard is basically a non-verbal emergency briefing. Its design is based on decades of safety research to get the most critical information—the risk of fire—across in the simplest, most effective way possible.

The table below breaks down these visual elements to give you an even clearer picture.

Flammable Liquid Placard Elements Explained

The design of a Class 3 placard is intentionally simple, allowing for quick identification of the hazard. Each part has a specific role in communicating the risk.

Placard Element Description Meaning and Purpose Red Background A solid, vibrant red colour covering the entire diamond shape. Immediately signals danger and is universally recognized as a warning for fire hazards. Flame Symbol A black, stylized flame icon located in the upper half of the placard. Visually communicates that the material is flammable and can ignite easily. Number ‘3’ The digit “3” is displayed in the bottom corner of the diamond. Designates the material as a Class 3 Flammable Liquid according to TDG and DOT regulations. Together, these elements form a clear, concise warning system that is critical for maintaining safety on our roads and at our facilities.

Why We Have Modern Hazmat Placarding

The strict, standardized placarding rules we follow today didn’t just appear out of nowhere. They were forged from the lessons of past disasters, where a simple lack of information led to truly devastating consequences. Think of modern hazmat placarding as a system born from necessity—a direct response designed to keep history from repeating itself.

Before we had these harmonized standards, transportation safety was a mess. It was a chaotic patchwork of inconsistent local rules. Imagine a shipment crossing from one province to another, suddenly subject to completely different marking requirements, or maybe none at all. This ambiguity was incredibly dangerous, leaving first responders and the public completely in the dark about the materials moving right through their communities.

This reactive approach only started to shift after major incidents forced regulators to finally take action. Each tragedy served as a painful but powerful catalyst, exposing critical gaps in safety protocols and proving just how badly we needed a universal language for hazard communication.

From Patchwork Rules to a Unified System

Getting to a unified system was a long and winding road. Early regulations were often narrow in scope and poorly enforced, leaving dangerous loopholes wide open. The history of hazardous materials placarding in North America, for example, goes all the way back to the mid-19th century, but the system we know today only really started coming together in the latter half of the 20th century.

The very first federal law covering the transport of explosives and flammables passed in 1866. It was prompted in part by a notorious wharf accident in San Francisco where an unmarked, leaking crate demonstrated the deadly cost of unidentified hazards. You can discover more about how this accident shaped 150 years of hazmat regulation on TheComplianceCenter.com.

Even with those early laws, it took a surprisingly long time for consistent placarding systems for common materials like gasoline to become the norm.

Today’s flammable liquids placard is so much more than a box to check on a compliance list. It’s a direct descendant of these hard-won safety lessons, representing a global agreement on how to communicate risk clearly and save lives.

This long evolution eventually led to the creation of regulatory bodies tasked with standardizing safety. Organizations like the United Nations began developing model regulations that would become the foundation for national rules all over the world.

The Role of Today’s Regulatory Bodies

Here in North America, that push for standardization gave us the systems managed by Transport Canada and the U.S. Department of Transportation. These agencies took those core principles of hazard communication and shaped them into the detailed regulations we follow today.

They carefully defined every single aspect of the flammable liquids placard:

- Precise Colour: That specific shade of red wasn’t an arbitrary choice; it was selected for maximum visibility in any condition.

- Standardized Symbol: The flame icon is instantly and universally understood, cutting right through language barriers.

- Hazard Class Number: The number ‘3‘ gives emergency crews an immediate, unambiguous classification to work with.

This level of detail is what makes the system work. It ensures that a placard seen on a highway in British Columbia carries the exact same meaning as one on a street in New York. This consistency is the absolute bedrock of modern transportation safety. It provides the clarity and predictability that was so dangerously missing in the past.

So, every time a compliant placard is fixed to a truck or an IBC, it’s a nod to this history and a real, tangible contribution to a safer supply chain for all of us.

Getting Placard Design and Placement Right

When it comes to the flammable liquids placard, thinking you can just slap any old red diamond on your truck is a fast track to a hefty fine. Being compliant means getting every detail right—from the exact measurements and the specific shade of red to where it’s mounted on the vehicle.

Inspectors from Transport Canada (TDG) and the U.S. Department of Transportation (DOT) have a sharp eye for these things. They don’t see them as minor details; they’re strict, non-negotiable rules. Getting a single specification wrong is often treated the same as having no placard at all. The entire system is built to ensure these warnings are impossible to miss, easy to read, and can stand up to the rigours of the road.

The Nitty-Gritty of Placard Design

A compliant placard isn’t just a sign; it’s a precisely engineered warning. Think of it as a uniform for hazardous goods—it has to be worn correctly to send the right signal instantly and universally.

These rules aren’t new. They’ve been refined over decades, with major U.S. standards being locked into law in the 1990s under Title 49 of the Code of Federal Regulations (49 CFR), Part 172, Subpart F. This was a huge step in aligning North American rules with global UN standards. For a fascinating look at how these regulations evolved, check out the history of hazmat regulations on HazmatNation.com.

Here’s what you need to get right every time:

- Dimensions: It has to be a diamond—a square tilted on its point—measuring at least 250 mm (9.84 inches) on all four sides. No exceptions.

- Border: A solid black line must run about 12.7 mm (0.5 inches) inside the edge. This small detail is crucial; it helps the diamond shape stand out, even from a distance or in poor visibility.

- Colour: The red isn’t just any red. It has to be a specific, vibrant shade that meets regulatory standards to ensure it grabs your attention immediately.

- Durability: The placard must be tough enough to survive a minimum of 30 days of road life. That means it has to be made of materials that won’t fade in the sun, peel in the rain, or tear off in the wind.

Key Takeaway: A flimsy piece of paper or a faded, cracked sign is an instant violation. Whether you use rigid aluminum, tough vinyl, or durable tagboard, it must stay intact and legible for the entire trip.

Where to Put the Placard: Visibility is Everything

The placement of a placard is just as critical as its design. The rule of thumb is simple: it needs to be seen. Anyone approaching the vehicle or container needs to be able to spot the warning from the side they’re on.

For a transport truck, this is straightforward. A flammable liquids placard must be displayed on all four sides: front, rear, and both left and right sides. This 360-degree visibility ensures that no matter how the truck is parked or situated during an emergency, first responders get the message loud and clear.

When you’re dealing with Intermediate Bulk Containers (IBCs), the logic is the same, but the application is a bit different.

- Large IBCs (over 450 L): If you’re shipping a single large IBC, you’ll generally need to placard at least two opposite sides of the container itself.

- Multiple IBCs: If the total weight of the IBCs on your truck hits the placarding threshold, the truck itself needs to be placarded on all four sides, just like any other hazmat load.

No matter where you place it, remember these three non-negotiables:

- Keep it Clear: The view of the placard can’t be blocked by anything—not by ladders, tarps, doors, or any other equipment.

- Make it Secure: It has to be securely fastened or locked into a holder. A placard that flies off on the highway is a serious problem.

- No Distractions: Keep it away from other logos, ads, or markings that could make it hard to see or cause confusion.

At the end of the day, getting the design and placement right isn’t just about ticking a box for compliance. It’s about making sure the flammable liquids placard can do its life-saving job, ensuring you’re upholding your part in keeping the public and emergency personnel safe.

When Do You Need to Use a Flammable Liquids Placard?

Knowing exactly when you need to slap a flammable liquids placard on your truck can feel like trying to solve a puzzle. It’s not as simple as carrying a single container of a hazardous product. The rules are all about quantity thresholds—the specific amount that separates a small, low-risk shipment from a larger load that could pose a serious threat to public safety.

Think of it as a risk assessment. A few small jugs of a flammable substance aren’t a huge concern, but a transport truck loaded with drums of it? That’s a different beast entirely. To manage that risk, both Transport Canada (TC) and the U.S. Department of Transportation (DOT) have drawn a clear line in the sand. Their regulations ensure that any shipment large enough to be a significant hazard is clearly identified for emergency responders.

Getting these weight limits right isn’t just about ticking a compliance box; it’s a non-negotiable part of shipping safely and responsibly. Let’s dig into the specifics of when that red diamond becomes mandatory.

The 454 kg (1,001 lbs) Rule Explained

If there’s one number to burn into your memory for North American hazmat shipping, it’s 454 kg (or 1,001 pounds). This is the magic number, the main threshold that triggers the need for placards for most Class 3 flammable liquids under both Canadian and American rules.

Now, this isn’t just the weight of the liquid itself. It’s the aggregate gross weight of all the hazardous materials you’re carrying that fall under Table 2 of the regulations. That means you need to add up the weight of the product plus its packaging—the drum, the tote, the pail, everything.

Let’s say you’re loading a truck with several 205-litre steel drums of ethanol. If the total weight of all those drums, including the steel and the ethanol inside, tips the scales at over 454 kg, your vehicle now legally needs a flammable liquids placard on all four sides. It’s a straightforward rule that takes the guesswork out of the equation.

Key Takeaway: The 454 kg (1,001 lbs) rule is your go-to benchmark. Once your total shipment of Table 2 hazardous materials hits this weight, placarding is no longer a choice—it’s the law.

This rule makes life easier for shippers and drivers. By creating a consistent and measurable standard, you can simply calculate your total load weight and know for sure whether you’ve crossed the regulatory line.

Understanding Important Exemptions

While the 454 kg rule is the main player, regulations are never quite that simple. There are always exceptions. Certain scenarios allow you to transport flammable liquids without a placard, even when the total weight might seem high enough to require one. Knowing these exemptions is key to avoiding fines—either for placarding when you don’t need to or, far worse, failing to placard when you should have.

Here are a couple of the most common exemptions you’ll run into:

- Limited Quantity Shipments: This refers to small, individual containers of hazardous materials that are packaged to an extremely high safety standard. Because the risk of a major spill from any single container is so low, these shipments are often exempt from placarding, even if the aggregate weight is significant.

- Combustible vs. Flammable Liquids: The difference here is huge. Flammable liquids, like gasoline, have a very low flash point, ignite easily, and are subject to strict placarding rules. Combustible liquids, like diesel fuel, have a higher flash point, making them less volatile. They have their own set of rules and often don’t need a ‘Flammable’ placard unless they’re being shipped in massive bulk quantities.

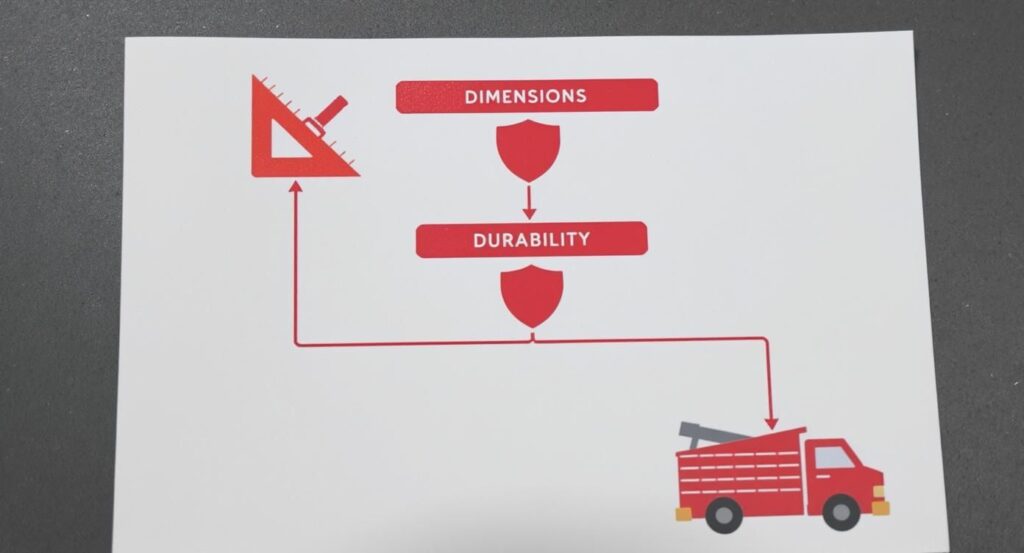

The infographic below gives a great high-level look at what goes into placard compliance, from the design itself to where it needs to be placed.

As you can see, compliance is a multi-step game. It’s not just about knowing when to use a placard; it’s also about ensuring its dimensions, durability, and placement are all by the book.

Placarding Thresholds US DOT vs Transport Canada

While the US and Canada have done a lot to align their dangerous goods regulations, you’ll still find subtle but important differences. If you’re running shipments across the border, knowing these little distinctions is absolutely critical for staying compliant.

The 454 kg (1,001 lbs) aggregate gross weight threshold is a good starting point, as it’s largely harmonized. The differences often pop up in the specific lists of materials or in the fine print of exemption criteria. For instance, how a certain chemical is classified might vary slightly between Transport Canada’s schedules and the DOT’s Hazardous Materials Table.

Here’s a quick comparison to help you keep the primary placarding rules straight for both countries.

Regulation Primary Placarding Threshold Key Considerations and Exemptions US DOT (49 CFR) 1,001 lbs (454 kg) aggregate gross weight for materials listed in Table 2. Placarding is mandatory for any quantity of a more hazardous material listed in Table 1. Special rules also apply to combustible liquids in non-bulk packaging. Transport Canada (TDG) 500 kg gross mass for most dangerous goods. TDG offers a general 500 kg exemption, but it’s not a blanket rule—it doesn’t apply to every hazard class. You have to consult the TDG Regulations for your specific materials. At the end of the day, the buck stops with the shipper. It’s your responsibility to verify the exact regulations that apply to your load. Always, always check the latest version of the TDG Regulations or the DOT’s 49 CFR to confirm your placarding duties before your wheels hit the pavement.

Common Placarding Mistakes to Avoid

Knowing the rules for a flammable liquids placard is one thing, but avoiding common, real-world mistakes is what really matters during a roadside inspection. These inspections are notoriously thorough, and even small errors can lead to big fines, frustrating delays, and out-of-service orders. More than just a headache, these mistakes are serious failures in safety communication.

Most violations I see boil down to simple oversights—a misunderstanding of the rules or a mix-up between different types of placards. By getting familiar with these frequent slip-ups, you can build a quick self-audit into your process to make sure every load is compliant before it even hits the road.

Using the Wrong Placard

This is probably the most common—and most avoidable—mistake out there. The visual differences between placards can seem minor, but to an inspector, they signal entirely different hazards. Confusing a ‘Flammable’ placard with a ‘Combustible’ one is a classic trip-up.

In fact, the Commercial Vehicle Safety Alliance (CVSA) often points this out as a recurring issue. Inspectors frequently see the combustible placard used for materials that are clearly classified as flammable. For example, things like gasoline (UN1203) or crude oil (UN1267) absolutely must have the solid red “Flammable 3” placard when you’re shipping them in bulk. You can dig into the full details on placarding errors from the CVSA.

The bottom line is this: never rely on memory or assumptions. Always double-check the shipping documents and the material’s Safety Data Sheet (SDS) to confirm the hazard class and flash point.

Incorrect Placard Placement

Having the right placard doesn’t do any good if no one can see it. The placement rules are strict for a good reason: they give first responders a clear 360-degree view of the hazard, no matter which direction they approach from. A placard tucked behind a ladder or covered by a tarp is as good as no placard at all.

Watch out for these common placement mistakes:

- Obstruction: Don’t put placards where they can be blocked by truck equipment, doors, or even mud flaps. That’s an instant violation.

- Insecure Mounting: Using tape or other flimsy methods that can fail in bad weather is a no-go. Placards must be securely fixed in a holder or stuck directly to the surface.

- Insufficient Coverage: Forgetting to put placards on all four sides of the vehicle is another easy way to get flagged.

Here’s a simple test: if you have to move something out of the way to see the placard clearly, it’s in the wrong spot.

Using Worn or Illegible Placards

A flammable liquids placard is a communication tool. If it’s unreadable, it’s failed its one job. The regulations demand that placards stay legible for the entire trip and are tough enough to handle at least 30 days of exposure to the elements.

Over time, placards fade in the sun, get torn by the wind, or become caked in road grime. A sign that was perfectly fine when it left the yard can become a violation halfway through the journey. This is why you can’t just ‘set it and forget it’—regular checks are crucial.

Proactive Compliance Checklist

To sidestep these common issues, just build this quick check into your pre-trip inspection routine:

- Verify the Placard: Does the placard on the truck match the hazard class on the shipping papers?

- Check for Wear: Is the placard clean? Are there any tears? Is the colour still vibrant or has it faded?

- Confirm Placement: Is there a placard on all four required sides of the vehicle?

- Ensure Visibility: Can you see each placard clearly without anything blocking the view?

Making these steps a habit is the best way to cut your risk of fines and, more importantly, contribute to a safer environment on the road.

Sourcing Compliant Placards and Containers

Knowing the rules for a flammable liquids placard is a great start, but true compliance happens when you have the right gear in hand. Getting both your placards and containers up to code is non-negotiable if you want to avoid hefty fines, frustrating shipping delays, and—most importantly—serious safety incidents. It’s about looking at the entire system, not just the sticker on the side.

A compliant placard has to be tough. Regulations are clear that it needs to stay legible and fully attached for at least 30 days of exposure to typical transport conditions. This durability requirement means flimsy, cheap materials just won’t cut it. You need to be looking for placards made from materials designed to withstand the rigours of the road.

Your best bets for materials are:

- Rigid Aluminum: This is a fantastic, long-lasting choice. It won’t bend or tear, making it perfect for permanent mounting on trucks or dedicated containers that see a lot of use.

- Adhesive Vinyl: A strong, flexible option that sticks securely to smooth container surfaces. Good quality vinyl will resist peeling, fading from UV exposure, and damage from rain or snow.

- Durable Tagboard: A more budget-friendly solution, usually for single trips. Just make sure it’s thick and sturdy enough to survive the entire journey without falling apart.

The Placard and Container Work Together

Think of the placard and the container as a team. The placard is just the messenger, warning everyone about what’s inside. If the container itself isn’t up to the task, that warning becomes almost meaningless. Slapping a proper flammable liquids placard on a damaged or non-compliant container is a recipe for disaster.

This is especially true when you’re moving liquids in Intermediate Bulk Containers (IBCs). You absolutely must use certified UN/DOT-rated IBCs that have been specifically designed and tested for flammable materials. These totes go through intense testing to prove they can handle the pressure, impact, and vibration of transport without failing. Trying to use a standard water tote for flammable chemicals isn’t just cutting a corner; it’s a serious violation.

When you’re choosing your equipment, you’re really building an integrated safety system. You can get a better sense of what’s required by exploring options for chemical IBC totes built for these exact purposes.

A compliant placard on a non-rated container is like putting a fire alarm on a house made of straw. The warning is useless if the structure itself isn’t built to manage the risk. True safety and compliance come from ensuring both parts meet all regulatory standards.

Vetting Your Suppliers

To make sure everything you buy is genuinely compliant, you have to be smart about where you source it from. A reputable supplier does more than just sell you a product; they provide the paperwork to back up their claims and prove everything meets North American safety standards.

Before you buy any placards or containers, always ask for documentation that verifies they meet both Transport Canada and US DOT specifications. This could be a manufacturer’s certificate of compliance or a technical spec sheet that details material durability and design accuracy. A supplier who knows their stuff will have this information ready to go, giving you peace of mind that your entire shipping setup is safe, secure, and fully compliant.

Answering Your Placarding Questions

Even after you’ve got a handle on the main rules, real-world situations always bring up specific questions about flammable liquids placards. The world of dangerous goods transport is full of little details, and getting them right is the key to shipping with confidence and staying compliant. Let’s tackle some of the most common questions we hear from folks in the field.

We’ve put these answers together to be straightforward and practical, aiming to clear up any confusion you might still have.

Can I Use a Placard with a UN Number?

You bet. In fact, sometimes you have to. A basic flammable liquids placard just has the flame symbol and the number ‘3’. But you’ve likely seen placards that also feature a four-digit number right in the middle—that’s the UN identification number.

Think of it as adding a crucial layer of detail. While the ‘3’ tells first responders they’re dealing with a flammable liquid, the UN number tells them exactly which one. For instance, UN1203 is gasoline, and UN1170 is ethanol. This specific ID is often mandatory for large bulk shipments or particularly hazardous materials, as it lets emergency crews instantly look up substance-specific protocols in their guidebooks. For many other shipments, it might be optional, but it’s always good practice.

What Is the Difference Between Flammable and Combustible?

This is a big one, and it all boils down to a single, critical property: the flash point. Simply put, the flash point is the lowest temperature at which a liquid produces enough vapour to catch fire if an ignition source is nearby.

- Flammable Liquids (Class 3): These are the more volatile of the two. With a flash point at or below 60°C (140°F), they can easily ignite at everyday working temperatures, posing a serious fire risk. Gasoline is the classic example.

- Combustible Liquids: These guys need a bit more encouragement to ignite. Their flash point is higher—above 60°C (140°F)—which means they are less volatile. Diesel fuel is a perfect example of a combustible liquid.

Getting this classification right is everything. It determines which placard you need and the handling precautions you must take. Mistaking one for the other is a frequent and serious compliance mistake, so always check the material’s Safety Data Sheet (SDS) to be sure.

The core takeaway is simple: flammable liquids catch fire easily, while combustible liquids require more heat to ignite. This difference dictates which placard you must use and the handling precautions you need to take.

Do I Remove Placards from Empty Containers?

Not so fast. According to both Transport Canada and DOT regulations, a container isn’t truly “empty” until it has been thoroughly cleaned and purged of all hazardous residue and vapours. An uncleaned drum or IBC that just held a flammable liquid can still be full of enough vapour to pose a major fire or explosion risk.

Because of this lingering danger, the flammable liquids placard must stay on the container until it’s properly decontaminated. If you’re shipping an “empty” but uncleaned container, you absolutely have to keep the placards on. You might also add markings like “Residue: Last Contained [Product Name]” to give handlers the full picture.

For more detailed answers to your shipping questions, you can always explore our comprehensive FAQ page.

For compliant, UN/DOT-rated IBCs designed to safely transport your flammable liquids, trust IBC Tanks Canada. We provide the reliable containers and components you need to meet regulatory standards and keep your operations moving safely. https://ibctanks.ca

Article created using Outrank