Your Guide to Portable Water Tanks

Think of a portable water tank as your personal, on-demand water supply, ready to be moved and set up wherever you need it. They're a common sight everywhere from remote construction sites in Alberta to sprawling agricultural operations in the Prairies. For countless Canadian industries, these tanks are a vital piece of equipment, providing a flexible and reliable source of water.

Your On-Demand Water Toolkit

It helps to see portable water tanks as more than just containers; they are a versatile 'water toolkit.' A mechanic doesn't use the same wrench for every bolt, and in the same way, different tanks are built to solve different water storage problems. While their main job is simple—store and move water—the ways they're used are incredibly varied.

Picture a crew building a new highway miles from the nearest town. They need water for everything from mixing concrete to keeping dust down and cleaning their gear. A tough, high-capacity poly tank strapped to a truck bed isn't just a convenience; it's their lifeline, delivering thousands of litres of water right to the work zone.

Or, think of a farmer using rotational grazing. When the cattle move to a new pasture, their water source has to follow. A smaller, towable tank with a simple gravity-fed trough keeps the animals hydrated without the need to build expensive, permanent pipelines. That's the real magic of portable water solutions—they go where you go.

More Than Just a Container

The true strength of these tanks is their adaptability. They fill the void when permanent water lines are out of reach, impractical, or just too costly to install. This makes them essential in a huge range of situations:

- Emergency Response: Getting clean drinking water to a community after a flood or fire.

- Event Management: Supplying water for sinks and hydration stations at music festivals or outdoor markets.

- Agriculture: Irrigating remote fields or watering livestock far from the main barn.

- Industrial Use: Keeping process water or even chemicals safely contained in a movable unit.

A well-chosen portable water tank is more than just a piece of equipment; it's a strategic asset that keeps your operation running smoothly. It gives you the freedom to work in places that would otherwise be off-limits, turning logistical headaches into simple tasks.

What You Will Learn in This Guide

To make sure you pick the right tool for the job, this guide will walk you through everything you need to know. We’ll explore the main types of portable water tanks, from solid poly tanks to collapsible bladders and the ever-popular IBC totes. We'll also get into the nitty-gritty of materials, so you'll understand why one tank is safe for drinking water while another is not.

Finally, we’ll look at what to consider for specific industries, how to install your tank properly, and the maintenance required to keep it in top shape for years to come. By the time you're done, you'll have a solid grasp of how these systems work and feel confident choosing the perfect one for your needs.

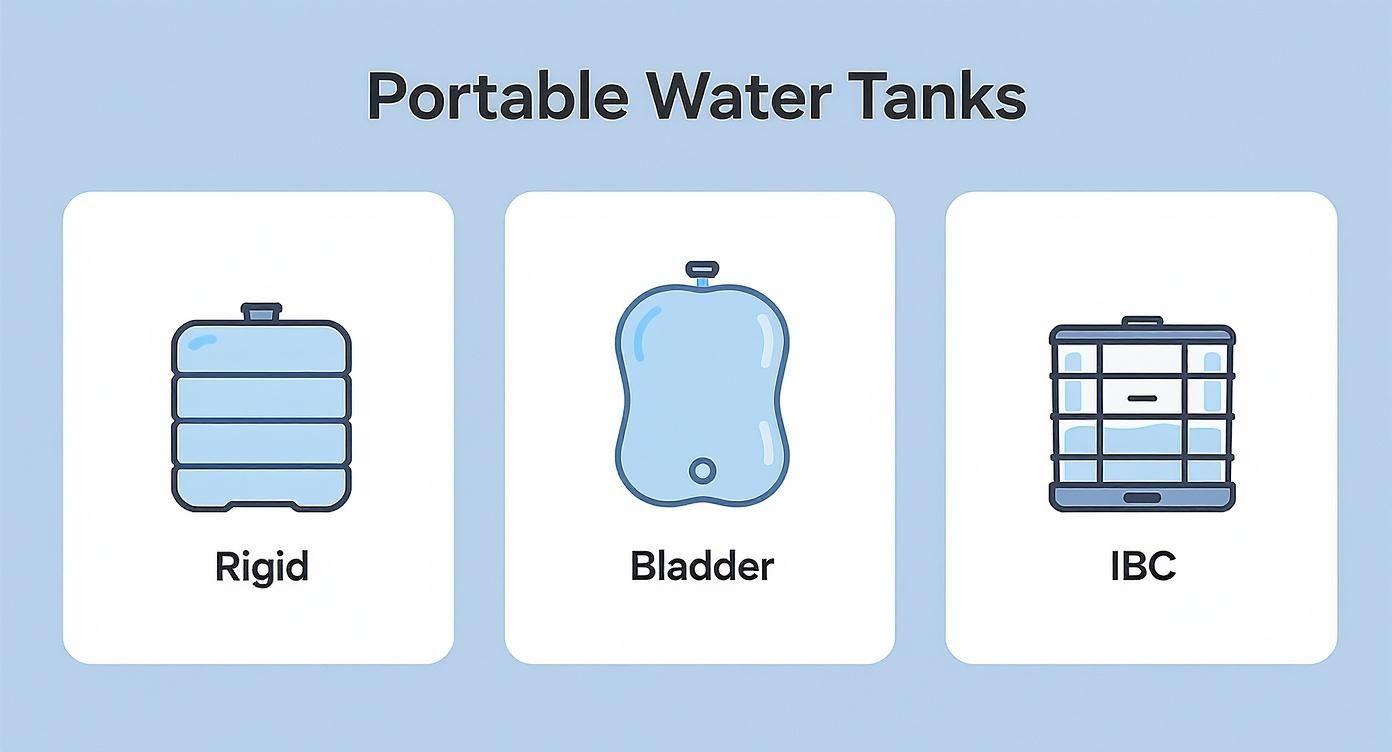

Comparing the Main Types of Portable Water Tanks

Picking the right portable water tank is a bit like choosing the right tool for a job. You wouldn't bring a sledgehammer to hang a picture frame, right? In the same way, the world of portable water tanks has its own specialized gear, and understanding the key differences is the first step to making a smart choice.

The three main players you'll run into are Rigid Poly Tanks, Collapsible Bladder Tanks, and the ever-present Intermediate Bulk Containers (IBCs). They all hold water, but how they do it—and what they're best at—couldn't be more different.

Let's break down what makes each one tick.

Rigid Polyethylene Tanks: The Workhorse

Think of a rigid poly tank as the trusty pickup truck of water storage. These things are built to last. Made from a single, solid piece of high-density polyethylene (HDPE), they're incredibly tough and can take a real beating from punctures, impacts, and the harsh Canadian elements. From scorching summer sun to deep winter freezes, a good poly tank just keeps going.

This is why they're the go-to choice when durability is everything. You'll see them mounted on trailers for dust control on construction sites, strapped into truck beds for rural firefighting, or used as a mobile water source for livestock. They’re designed to handle the bumps and scrapes of daily work without skipping a beat.

Of course, their biggest strength is also their main drawback. They're rigid, meaning they take up the same amount of space whether they're full or empty. That makes them less than ideal if you're tight on storage space or need something you can pack up and move easily.

- Key Strength: Extreme durability and built-in resistance to physical damage.

- Best For: Agriculture, construction, and any job that needs a rugged, long-term solution.

- Consideration: They don’t collapse, so they require significant space for transport and storage, even when empty.

Collapsible Bladder Tanks: The Rapid Responder

If the rigid tank is a pickup, the collapsible bladder tank is like one of those high-tech, foldable utility trailers. You might hear them called "pillow tanks," and for good reason. Made from heavy-duty, flexible fabrics like PVC or polyurethane, their whole purpose is portability and saving space.

When they’re empty, you can fold or roll them into a surprisingly small package. This makes them absolute lifesavers for emergency response teams. First responders can deploy several large-capacity bladder tanks in minutes, setting up a temporary water depot for disaster relief or firefighting support. They’re also a favourite for temporary work camps, music festivals, and military operations—anywhere you need a lot of water right now.

Bladder tanks solve a simple but critical problem: how to store thousands of litres of water today in a space that needs to be empty and clear tomorrow. Their ability to go from a compact bundle to a high-capacity reservoir is their defining advantage.

The trade-off for all this flexibility is a bit of ruggedness. While the material is tough, they are more vulnerable to punctures from sharp rocks or debris on the ground compared to a hard-shelled tank. A little bit of ground prep goes a long way in keeping them in good shape.

Intermediate Bulk Containers (IBCs): The Logistics Champion

Intermediate Bulk Containers, better known as IBC totes, are the standardized shipping containers of the liquid world. They are a brilliant combination of a tough inner plastic bottle cradled inside a protective outer steel cage. This design gives you the safe containment of a poly tank with the structural muscle needed for stacking and transport.

Their uniform, cube-like shape is their superpower. IBCs are designed from the ground up to be moved efficiently with a forklift or pallet jack, and you can stack them to make the most of your warehouse or truck space. This standardization has made them a cornerstone of industrial logistics for everything from water and food-grade syrups to non-hazardous chemicals.

For anyone needing to plug water storage into an existing supply chain, the IBC is almost always the most logical choice. It’s easy to see how a versatile bulk container like an IBC can streamline all sorts of industrial workflows. The main limit? They typically come in standard sizes, like 1040 litres (275 gallons), so they might not be the right fit for jobs needing a much larger single tank.

To help you see it all side-by-side, here's a quick cheat sheet.

Portable Water Tank Types at a Glance

This table gives you a quick snapshot of the three main tank types, helping you match their features to what you need to get done.

| Tank Type | Key Feature | Common Capacity Range | Ideal Use Cases |

|---|---|---|---|

| Rigid Poly Tank | Unmatched durability and impact resistance. | 200 – 10,000 Litres | Construction dust control, agricultural water hauling, mobile pressure washing. |

| Collapsible Bladder | Folds down for compact storage and transport. | 500 – 50,000+ Litres | Emergency water supply, remote work camps, temporary event hydration. |

| IBC Tote | Stackable, caged design for easy logistics. | 1040 – 1250 Litres | Industrial liquid transport, food ingredient storage, job site water supply. |

At the end of the day, the best portable water tank is the one that fits your specific needs. It's all about balancing durability, portability, and capacity to find the perfect match for your work.

Understanding Tank Materials and Construction

When you're choosing a portable water tank, the material it's made from is everything. It dictates the tank's durability, its lifespan, and most importantly, its safety. Get this right, and you have a reliable asset that will serve you for years; get it wrong, and you could be looking at a container that fails just when you need it most.

For most of the rigid poly tanks and IBCs you'll see on the market, the hero material is High-Density Polyethylene (HDPE). You can think of it as the gold standard in modern tank manufacturing. This isn't your average plastic—it's a seriously tough polymer engineered for strength and purity.

Its unique molecular structure gives it incredible resistance to impacts, punctures, and the general abuse that comes with being on a busy worksite or farm. This is exactly why HDPE tanks hold up so well against the tough Canadian elements, from blistering summer sun to deep winter freezes, without cracking or becoming brittle.

This visual helps break down the main categories of portable water tanks, showing how their form is tied directly to their function.

As you can see, rigid tanks, bladders, and IBCs each have their own place, all determined by how they're built and what they're made of.

Beyond Just Plastic

While HDPE is king for rigid tanks, flexible bladder tanks are a different story. They need to be foldable and portable, so they're typically made from heavy-duty, pliable fabrics like Polyvinyl Chloride (PVC) or Polyurethane. These materials are specifically chosen for their ability to be packed up small and deployed quickly without getting damaged.

The choice really comes down to the job at hand:

- HDPE: The go-to for structured, long-lasting containers that will face physical stress and year-round weather.

- PVC/Polyurethane: Perfect for temporary, large-volume storage where getting it there and setting it up fast is the main goal.

The Critical Difference: Food-Grade vs. Non-Food-Grade

This is where the conversation shifts from durability to public health, and it's a distinction you can't afford to ignore. Not all plastics are safe for storing drinking water.

A food-grade tank is made from 100% virgin resin. That means it’s pure, brand-new plastic with absolutely no recycled content or mystery additives. This is your guarantee that no harmful chemicals will leach out of the tank walls and into your water.

On the other hand, non-food-grade tanks might contain recycled plastics or other materials not tested for food safety. They’re perfectly fine for non-potable uses like dust control, irrigation, or construction, but they have no business holding water meant for people or animals to drink.

Why Certifications Matter

So, how can you be sure a tank is safe for drinking water? Look for an NSF/ANSI 61 certification. This is the official North American standard that confirms a product is safe for contact with potable water. Choosing certified potable water storage tanks isn't just a good idea—it's the only way to be certain your water will stay pure.

Even massive public water systems rely on certified portable storage. For example, California’s State Water Project often uses modular tanks for emergency supplies or during maintenance, proving just how vital these certified containers are for public infrastructure.

At the end of the day, a good portable water tank is the result of smart engineering and the right materials. By choosing a tank made for your specific needs—whether that's a UV-stabilized HDPE tank for agricultural use or an NSF-certified one for a community festival—you're investing in reliability and peace of mind.

How to Choose the Right Tank for Your Industry

Picking the right portable water tank isn't a one-size-fits-all deal. It’s all about matching the right tool to the job. The tank that’s perfect for a construction site could be a total disaster for an emergency response team. When you really get a handle on the unique challenges of your industry, you can pick a system that works for you—not against you—making your operation more efficient, safer, and dead reliable.

Think of it like choosing a vehicle. You wouldn't use a city car to haul feed across a muddy field; you'd get a tractor. It’s the same logic for portable water tanks. The specific demands of Canadian agriculture, construction, and emergency services all call for different, specialized solutions. Let's break down the best choices for each.

Agriculture Water Needs

In farming, water is everything. The problem is, it's not always where you need it to be. Farmers often work massive properties where laying permanent pipelines just isn't practical or affordable. This is where big, tough poly tanks become absolute essentials for day-to-day work.

Take a rotational grazing system, for example. As you move cattle or sheep to fresh pasture, their water source has to move with them. A towable poly tank hooked up to a simple gravity-fed trough gives them a constant supply of fresh water without you having to be there all the time. It’s an incredibly flexible setup that lets farmers get the most out of their land while keeping their herds healthy.

For irrigating crops, especially in those far-flung fields or during a dry spell, portable water tanks on a trailer can be a real lifesaver. A 5,000-litre poly tank can completely change the game, letting a farmer put water exactly where it's needed to protect a valuable crop from drought. For really big operations, looking into large water tanks can open up options designed for those massive demands.

Construction and Remote Work Sites

Construction sites are always changing, and they're often miles from the nearest municipal water hookup. But water is critical for everything from dust control and soil compaction to mixing concrete and washing down equipment. When it comes to construction, durability and mobility are king.

This is where rigid poly tanks really earn their keep. They are the undisputed workhorses of the industry because they can take a beating and handle harsh weather. You can mount them on truck beds or trailers to create a reliable on-site water source that moves as the project grows. Their thick, impact-resistant walls are built for the rough-and-tumble reality of a job site.

The idea of bringing a water supply right to where you need it isn’t new. Old structures like the Santa Ana water tower, built back in 1928, did the same thing for growing towns by providing a stable, elevated water supply. You can see how these early storage solutions helped shape regional development.

This time-tested concept of localized water storage is exactly what makes modern portable tanks so effective on today's work sites.

Emergency Services and Rapid Deployment

When a crisis hits, every second counts. For emergency crews, firefighters, and disaster relief teams, being able to set up a massive water source in minutes can be the difference between life and death. This is where collapsible bladder tanks, or pillow tanks, are in a class of their own.

Picture a wildfire burning in a remote forest. Crews can airlift in folded bladder tanks, fill them up fast, and create a temporary reservoir to feed their pumps. This gives them way more reach and staying power. Because they’re so compact when empty, they're easy to transport and store, ready to go at a moment's notice.

These tanks are also crucial for getting clean drinking water to communities after a natural disaster knocks out the main supply. A single large bladder tank can provide potable water for hundreds of people, making it a non-negotiable piece of gear in any emergency plan.

Specialized Industrial Applications

Beyond those big three, portable water tanks are used in countless other specialized industries all across Canada. Their sheer adaptability makes them incredibly useful in all sorts of situations.

- Event Management: Supplying water for food vendors, sanitation stations, and keeping crowds hydrated at festivals and outdoor concerts.

- Mining and Exploration: Providing water for drilling and dust control at remote exploration camps.

- Food and Beverage: Storing and moving process water or liquid ingredients. In industries like brewing, water quality is critical. Learn about pure water applications in breweries and you'll see how specific needs drive the choice of storage tank.

- Residential Use: Harvesting rainwater for the garden or having a backup water supply for homes in rural areas.

At the end of the day, picking the right tank just comes down to taking a clear look at what your industry really needs. By matching the tank’s material, size, and design to the job, you’ll make sure your water supply is an asset you can count on, not just another logistical headache.

Best Practices for Tank Installation and Maintenance

Choosing the right portable water tank is only half the battle. To truly get your money's worth, you need to set it up correctly and look after it. Proper installation and a bit of routine maintenance are what ensure your tank works safely, reliably, and for a long, long time. This isn't just about preventing costly damage; it's about protecting the quality of the water you're storing.

Think of it like the foundation of a house. If it isn't solid and level from the start, you're just asking for problems down the road. A little prep work upfront makes all the difference.

Preparing Your Site for Installation

The very first thing you need to do—and arguably the most important—is prepare the ground where the tank will sit. An uneven surface or one littered with debris creates pressure points on the tank's base, which can easily lead to stress cracks and, eventually, failure.

Before you even think about placing your tank, make sure the site is:

- Completely Level: Grab a spirit level and check. Even a slight tilt can cause a massive imbalance when you've got thousands of litres of water sloshing around.

- Stable and Compact: The ground has to be firm enough to handle the tank's full weight without shifting or sinking.

- Clear of Debris: Get rid of any sharp rocks, sticks, or anything else that could puncture or gouge the bottom of the tank.

If you’re setting up a tank for a while, laying down a base of compacted sand or fine gravel is a great idea. It provides a stable, cushioned surface and is your best defence against premature tank failure.

Securing Your Portable Water Tank

Once the site is ready, you need to make sure that tank isn't going anywhere. An unsecured tank, even a heavy one, can be a serious safety hazard, especially when you're moving it or if you're in a high-wind area.

Proper installation is non-negotiable for safety and longevity. An improperly placed tank can fail under its own weight, turning a valuable asset into a liability. Always prioritize a stable, level foundation.

For any tank mounted on a trailer or truck bed, use high-quality, heavy-duty ratchet straps. Double-check that the straps are rated for the tank's full weight and hook them onto solid anchor points on the vehicle. This stops it from shifting in transit, which could cause an accident or wreck the tank itself.

If the tank is going to be stationary for a while, think about anchoring it down, particularly in places known for extreme weather. This ensures it stays put, whether it's full or empty.

Routine Maintenance and Cleaning

Just like any other piece of equipment, regular maintenance will keep your portable water tank in top shape. It helps you catch small issues before they snowball into big, expensive problems. A simple inspection checklist can make this a quick and easy job.

Here's what a good maintenance routine should look like:

- Visual Inspection: Give the tank a regular once-over. Look for any signs of cracks, bulging, or weird discoloration, paying close attention to corners and fittings.

- Check Fittings and Seals: Make sure all valves, lids, and seals are tight and not leaking. A tiny drip can waste a surprising amount of water over time.

- Clean the Interior: Every so often, you’ll need to clean the inside of the tank to stop sediment and algae from building up.

If you're using the tank for potable water, sanitization is key. After a good cleaning, rinse the tank with a mild bleach solution (about one part bleach to 100 parts water). Let it sit for a bit, then rinse it out thoroughly until you can't smell any chlorine. For tanks filled from sources like bore water, adding specialized filtration systems for tank and bore water is essential to keep the water safe and clean.

Your Top Questions About Portable Water Tanks, Answered

Alright, we’ve covered the different types of tanks, the materials they’re made from, and what they’re best used for. But I know from experience that this is where the real-world questions pop up. Think of this as the practical FAQ section, where we tackle the details that matter on the ground.

Getting these things right is what gives you the confidence to pick the perfect tank and use it safely for years to come. So, let’s jump into some of the most common questions we hear from folks all across Canada, from farmers out on the Prairies to construction crews in B.C.

Can I Just Use Any Portable Tank for Drinking Water?

Definitely not. If you take away only one thing from this guide, let it be this: for drinking water, you must use a tank that is specifically rated as "food-grade" or has an NSF/ANSI 61 certification.

This certification is your guarantee that the tank is built from 100% virgin, non-toxic materials that won't leach nasty chemicals into your water. Grabbing a non-certified tank, especially one made from recycled plastics or one that might have held chemicals before, is a serious health risk. It can easily contaminate your water supply, making it unsafe for you, your family, or your livestock.

When in doubt, assume it’s not safe. Always look for the food-grade or NSF certification mark before you buy. Your health depends on it.

How Do I Stop Algae from Growing in My Water Tank?

Algae is a classic headache, but thankfully, the fix is pretty simple. Algae needs one thing to survive: sunlight. Cut off its fuel source, and you’ve solved the problem.

Your best defence is to choose an opaque, dark-coloured tank. Black or dark green tanks are fantastic at blocking the UV rays that algae need for photosynthesis. This isn't a coincidence; most high-quality poly water tanks are made in these colours for this very reason.

What if you already have a lighter-coloured tank? You still have options:

- Find Some Shade: Tuck the tank into a shed, under a lean-to, or in any spot that keeps it out of direct sun.

- Keep Water Moving: Using the water regularly prevents it from sitting stagnant, which makes it much harder for algae to get a foothold.

- Clean It Out: As we covered in the maintenance section, a good periodic scrub removes any slime or buildup before it becomes a problem.

While these tricks work, starting with a dark, opaque tank is hands-down the easiest way to keep your water clean long-term.

How Long Does a Portable Poly Water Tank Last?

A well-made polyethylene water tank is a real workhorse. With a bit of common-sense care, you can easily expect it to last for 20 years or even longer. Of course, not all tanks are created equal, and a few key things affect that lifespan.

The number one factor is the plastic itself. Always look for tanks made with UV-stabilized resin. This means the plastic has special additives that prevent it from getting brittle and breaking down under the harsh Canadian sun. The tank's wall thickness also makes a big difference—thicker walls mean more strength and better resistance to bumps and scrapes over the years.

Finally, how you treat it matters. Always place your tank on a flat, stable surface that’s clear of sharp rocks or roots. Preventing physical stress and damage is the simplest way to get the most out of your investment.

Do I Need a Permit for a Portable Water Tank in Canada?

This is a classic "it depends" situation, as the rules can change quite a bit depending on where you are and what you’re doing.

For truly portable tanks—the kind you’d see on a trailer for farm use or strapped to a truck on a job site—you almost never need a permit. They’re considered equipment, not a permanent structure.

Things get a bit different when you set up a larger tank in a more permanent spot. For example, if you’re installing a big tank for a rainwater harvesting system or as a backup water source for your property, local bylaws might kick in. These rules usually cover things like:

- Placement: How far the tank needs to be from property lines or buildings.

- Foundation: What kind of base or pad is required to support the tank safely.

- Plumbing: Any specific codes for connecting the tank to your home or irrigation.

Before you install any large, stationary tank, your best move is to check with your local municipality. A quick call can save you a world of headaches later and ensure your setup is safe and fully compliant.

For a reliable supply of new, rebottled, and reconditioned portable water tanks and all the parts you need to keep them running, IBC Tanks Canada has you covered. Explore our full inventory and find the perfect solution for your industry at https://ibctanks.ca.